Why Joinery Design Matters in Industrial Hoppers

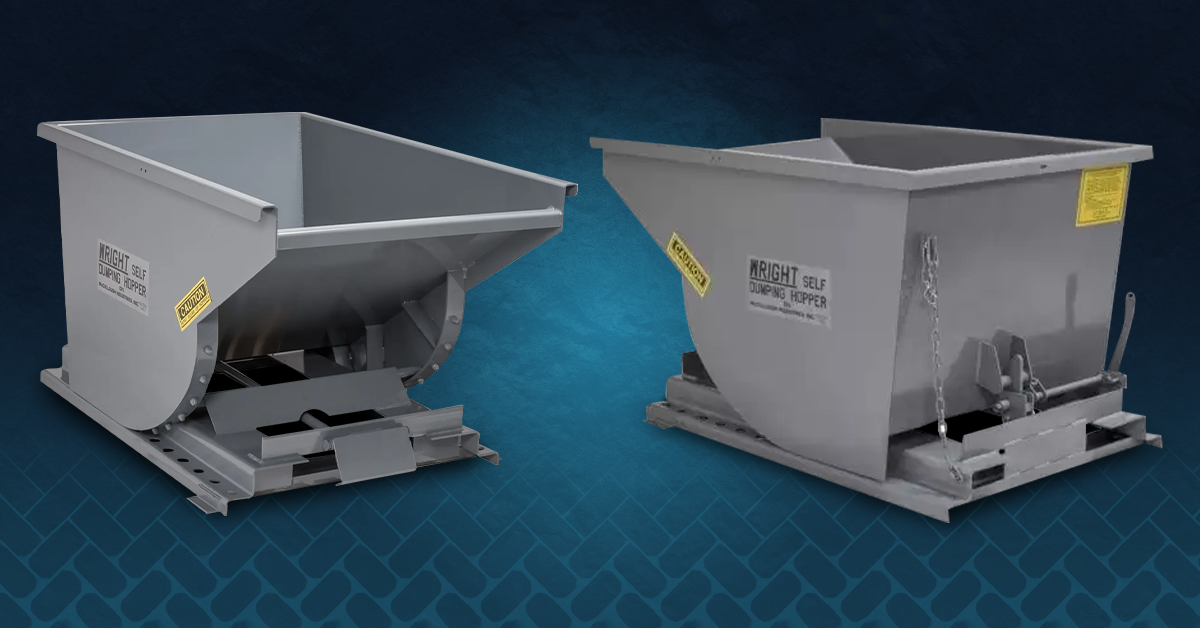

When you’re handling industrial scrap, chip waste, or fluid-laden materials, hopper construction isn’t just about steel gauge or capacity, it’s about how that steel is joined. At McCullough Industries, we offer seam-welded Wright® Self-Dumping Hoppers because joinery type directly affects your operation's safety, cleanliness, and maintenance over time.

In this article, we compare

seam-welded vs bolted hopper construction to help you understand which offers better performance in demanding environments. Spoiler alert: in almost every industrial scenario, seam welding wins.

What Is Seam Welding?

Seam welding is a fabrication method that joins metal parts using a continuous weld bead along the joint. Unlike spot welding or bolt fastening, seam welds create a

fluid-tight, permanent connection between hopper panels. At McCullough Industries, our hoppers are welded by skilled technicians using precision jigs to ensure strength and consistency across every unit.

Bolted Hopper Design: An Overview

Bolted hoppers are typically modular, allowing for disassembly or field repairs. In these designs, panels are connected using mechanical fasteners and flange-style seams. While this allows some flexibility, it also creates vulnerabilities in durability and leak resistance.

Key Differences at a Glance

| Feature | Seam-Welded Hoppers | Bolted Hoppers |

|---|---|---|

| Leak Resistance | Fully sealed, fluid-tight | Gaps between flanges |

| Structural Integrity | One-piece rigidity | Panel flex under load |

| Maintenance Requirements | Minimal | Regular bolt inspection & tightening |

| Debris Containment | Smooth interior walls | Crevices that trap shavings |

| Safety Profile | Fewer failure points | Risk of bolt failure or loosened seams |

| Best Use Case | Wet, oily, abrasive scrap | Light-duty, dry applications |

Why Seam-Welded Wright® Hoppers Are the Industry Standard

Our Wright® Self-Dumping Hoppers are fabricated using continuous seam welds to deliver:

- Leakproof Performance: Crucial for coolant-heavy chip loads, wet waste, or chemically treated scrap

- Durability Over Time: Seam welds don’t loosen with vibration or impact like bolts can

- Cleaner Operation: Welded interiors don’t trap metal slivers or grime

- Improved Safety: No bolts to shear or seams to split under pressure

These attributes make seam-welded hoppers ideal for high-frequency dumping, forklift transport, and environments with abrasive or oily waste.

Why Bolted Hoppers Still Exist

Despite their drawbacks, bolted hoppers are still found in lower-cost models or temporary-use bins. They're often marketed as "modular" or "easy to ship" solutions. While they may reduce upfront cost or allow onsite assembly, they come with long-term performance trade-offs.

Seam Welded = Leak Control

Especially in CNC or metal cutting environments, chip loads often carry coolant, oils, or other fluids. With bolted seams, even the best gaskets eventually degrade. Our seam-welded hoppers maintain containment integrity over years of use.

We also offer drain plugs and drip trays as add-ons for enhanced leak control. If you're handling fluid-soaked scrap, this combination keeps your floors clean and safe.

Weld Quality and Testing at McCullough

Every Wright® hopper is fabricated in-house in Ohio and inspected by our weld team before it ever leaves the floor. We test:

- Weld penetration and bead quality

- Fork pocket strength

- Dump cycle performance

- Compatibility with forklift tines and rotators

We build these units to withstand real industrial use, not just showroom conditions.

The Cleanability Factor

If your hopper is trapping debris, it’s costing you labor hours and compromising safety. Seam-welded interiors present smooth, uninterrupted surfaces that make cleanup faster and reduce bacterial growth. This is especially useful in packaging, recycling, and food-adjacent operations.

Service Longevity: Seam Welded Units Outlast Bolted Ones

Bolted bins often require fastener retightening, rust control, or eventual panel replacement. With fully welded Wright® hoppers, you get years of service with almost no maintenance beyond normal inspections.

Customizations That Preserve Weld Integrity

Our engineers can integrate modifications into the welded structure without sacrificing durability. This includes:

- Gasketed safety lids

- Dual-chamber wall partitions

- Drain ports with pipe threading

- Liner-ready interiors

- Splash-resistant dump lips

These upgrades are seam-integrated - not bolted on as afterthoughts.

FAQs: Seam-Welded vs Bolted Dump Hoppers

Why do bolted hoppers leak over time?

Because bolts can loosen and gasket materials degrade, bolted hoppers lose their seal in high-use or wet conditions.

Can I replace a bolted hopper with a welded model without facility changes?

Yes. Wright® hoppers match standard forklift specs, and our team can help spec a unit to your current footprint.

Are seam-welded hoppers heavier?

Not significantly. Wright® hoppers use heavy-gauge steel regardless of joinery, and the weight difference is minimal compared to the performance gain.

Is there ever a reason to choose a bolted hopper?

Only if you're working with dry, lightweight material in a temporary setting. For permanent or fluid-prone workflows, seam welding is the clear choice.

How can I tell if a hopper is fully welded?

Look for continuous beads on all interior seams and absence of external flanges or bolt heads.

Let’s Upgrade Your Hopper Setup

If your current bins are leaking, flexing, or rusting at the seams, it’s time to step up to a fully welded solution. At McCullough Industries, we fabricate our Wright® Self-Dumping Hoppers with long-term safety, cleanliness, and performance in mind.